When I first decided I wanted to to get into screen printing a few months ago I really had no idea

what was involved. I am an artist and I knew that I wanted to print my own designs but that was about it, so when I first started to look around for screens I went to my local art supply store and they were able to provide me with my first silk screen and a squeegee for a fair price, however, I recommend that you find a screen print wholesaler and deal with them directly. This way you will save yourself a whole lot of cash as well as tapping into the supply line for everything you will need.

I recommend using the following suppliers:

If you are in New Zealand

use CCG Industries: Screen printing.

If you are in USA use

Catspit Productions, LLC.

You can screen print without a carousel.

With the average cost of a

screen printing carousel being between $1500 - $2500 I could not afford one to

start out. Instead, get a friend to help hold the screen firmly in place while you use the squeegee to apply the ink to the screen then have them lift it away, it really is that easy. Just make sure the screen does not move while you're printing. I use a flat piece of wood slipped inside the shirt to keep it flat and prevent ink from bleeding through to the black layer. A day may come when you are printing the volume to

afford a carousel, but to begin with you can get by without one and save a

whole bunch of money. As I am writing this I am running my entire operation off

1 trestle table with the help of a friend to hold the screen when I print,

that's it.

|

| Have a friend to help hold the screen firmly in place while you print. Push ink forward with squeegee , drag back. |

How to use photo emulsion on the cheap.

Photo emulsion is easy to

use in the right conditions. To use your artwork on your screen as a stencil you

will first need to coat the screen with a photo emulsion in total darkness,

then dry it in total darkness until the emulsion sets, then finally you can

place your artwork transparency onto the screen and expose it to light to make

a stencil from your artwork.

Buy a darkroom safe light

The best way to work with

the photo emulsion is in safe light conditions. A darkroom safe light lets you

work with the photo emulsion in safe light conditions so that you can see what you’re

doing when mixing the emulsion and coating the screen without exposing it to UV

light (sunlight, light from light bulbs). Jump on Trademe or Ebay and find a

Kodak darkroom safe light (or equivalent). With everything photographic moving

to digital these days safe lights are no longer in demand and you should be

able to buy one for around $20 (I did).

Buy some photo emulsion and a scoop coater

You can buy this directly

from your screen print supplier.

If you are in New Zealand

use CCG Industries: Screen printing.

If you are in USA use

Catspit Productions, LLC.

Coating the Screen

Turn off all other lights;

plug in your safe light. You are now working in safe light conditions. Mix your

photo emulsion as specified by the manufacturer. Poor the mixed emulsion into

your scoop coater and use it to coat the underside of the screen.

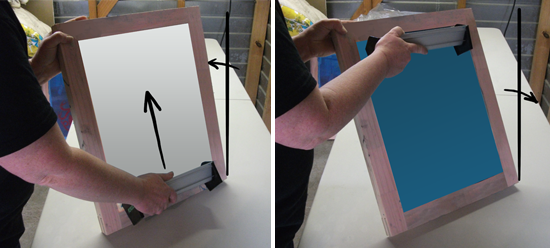

|

| Coating the Screen. Tilt screen back slightly and slide up the screen. Tilt back when at top. Pull away. |

Drying the screen

Now the screen needs to be

left to dry face down in a dark place, where no light can reach it. Photo

emulsion takes a while to dry so plan for safe light conditions to dry it for a

few days away form daylight (or any other UV light). For months I used a large

suitcase to store the screen in while it dried. I put some blocks in each end of the case to hold the screen away from the bottom and placed the screen inside face down, zipped up, and then covered the suitcase with a blanket to ensure no light entered and waited until it dried. In winter without heat

applied this can take a week to dry properly. In summer it will dry much

faster. If you can apply a low heat source (fan heater for example) it will dry

much faster. Only check on the screen under safe light conditions and only

expose your artwork when the photo emulsion is completely dry, it hardens. I

recently got a new laptop to use with Photoshop, and have modified the

cardboard box the laptop came in to use as a light safe box for drying photo

emulsion coated screens in. It really can be as cheap and simple as a cardboard

box well sealed with black duct tape. A few blocks in each end to keep the

screen off the bottom, the lid closed up with a blanket thrown over it to make

sure it is light safe. Ghetto styles!

For more on working with

photo emulsion checkout Catspit Productions, LLC.

Build a super low cost exposure unit:

If you want to buy a large

vacuum sealing exposure unit it will cost from $999 - $2500.

I couldn't afford that, I

still cant. Here is how I expose my screens, its super cheap and easy.

Buy a lamp for an exposure unit for under $30.

Your local hardware supply

store sells 500wat halogen work-lights for around $30 (cheaper in USA). They

generally have a black housing and clear glass lens at the front with a wire

grill covering it. Start by removing the grill and glass from the front. It is

a UV filter and when you expose your artwork to your screen you will want

maximum UV exposure. If you have a shed, attach a piece of wood 32cm from the

trestle table you will be exposing your screen on. I attached the wood with a

hinge so I can fold the lamp up and away when not in use. If you don't have

access to the bare beams of a shed wall to rig up your exposure unit then use whatever

is at hand. I have seen people use a guitar stand to hold the lamp the correct

distance from the screen while it exposes (32cm).

Next you need to buy some

foam rubber to fit under your screen. The idea here is that the foam is

slightly deeper than the screen so that it pushes the screen up from the table

when the screen in placed under the lamp face up.

Buy 3m of plain black cloth

fabric. Cheap as chips. We will use some of this to cover our foam rubber and

the rest will be used to cover the area under our screen when we expose it.

Wrap the foam in black

fabric so that it is completely covered. I used liquid nails to attach the

fabric to the screen as I cannot sew. As long as the foam is covered in the

black plain cloth it will be fine.

Buy a peace of 1 quarter

plate glass with 0 UV rating (or the lowest UV rating you can get so that it

will let the maximum UV rays though possible). Measure it so that it is big

enough to cover your artwork holding it down flat onto the screen. Slightly

larger than the inside edge of the screen works fine. Have the edges of the

glass sanded so that you can handle it safely without getting cut. Any glass

supply store can do this for you.

And that is all the kit you

need to get started. You will have some black fabric left over, when you are

ready to expose your screen start by covering the table area with the remaining

fabric.

How to expose a screen

I recommend doing this procedure

at night. Parts of the process need to be done in safe light conditions. For

washing out the screen you will need a garden hose with a pressure or jet

nozzle, or you may want to use a water blaster or pressure washer if you have

one.

Kill all the lights and turn

on your safe light. Now in safe light conditions get out your screen which is

already coated with now dried photo emulsion. Put the foam packing in the

underside of the screen. Place the screen in the centre of the black cloth,

foam down, screen up. Place the artwork on the screen paying attention to which

way the art will print, place the glass over the artwork so that it holds it

flat against the screen. Turn on the 500wat work-light and expose the screen

for 5 minutes.

After five minutes turn off

the 500wat work-light. Turn your safe light back on. Take the screen and wash

it out, I recommend doing this process at night to eliminate light from

affecting your screen result. Start by soaking your whole screen in water on a

soft spray, and then turn up the pressure and blast away the unwanted emulsion

from your new stencil. It can take a while to get the emulsion to wash out

using just a garden hose, be patient or use a high pressure washer to speed

things up.

Dry your screen off and your screen is done, you are ready to print!

|

| Start by soaking your whole screen in water on a soft spray, and then turn up the pressure and blast away. |

Dry your screen off and your screen is done, you are ready to print!

For more useful information on screen printing check out Catspit Productions, LLC.

|

| The final product |

Also I recommend reading

Threads Not Dead, by Jeff Finley of Gomedia for an in-depth look at apparel

industry and how to launch your own clothing line.

I got into this for the love

of art and to earn some side income, chances are it’s the same for you to.

Earning some cash along the way is good to. One day I hope to launch my own

clothing line and go big time. In the mean time I try to simplify the print process

so that it is manageable and affordable while I am still working a day job. I

hope you have found some value in these ghetto methods.

Take it easy,

paintedbrain

Wow thanks I like your style and you make it sound easy :)

ReplyDeletenice mock up -- wheres the final product?

ReplyDeleteHey thanks. Just mock ups at this stage.

ReplyDeleteNice information about screen printing.

ReplyDeleteApparel Boxes

This post is so informative and makes a very nice image on the topic in my mind. It is the first time I visit your blog, but I was extremely impressed. Keep posting as I am gonna come to read it everyday!

ReplyDeletebanners

I personally really appreciate your article. This is a great post . thanks sharing screen printing T-shirts ,Keep posting...

ReplyDelete